The

Anti-Reflection Lens Coating Course, which follows, begins with

a brief history, then goes on to discuss the Patient benefits

of AR. It continues with a description of some technical aspects

such as Constructive and Destructive Interference, and then

provides an overview of the current technologies and equipment

used in the actual AR coating process. . (See complete Free

Courses List. See Training

Resources.)

The

second part of the course describes in-office techniques that

should be used to help prepare lenses for the AR coating process

and includes tips for cutting and edging lenses as well as the

use of AR with certain cosmetic lens treatments such as tinting

and edge polishing. The course concludes with techniques that

can be used for effectively presenting AR coating to Patients.

Much

of the information contained in this course is provided courtesy

of the AR Council. The AR Council is a non-profit industry association,

that was founded in 1989 and is comprised of a variety of companies

with a strong interest in anti-reflective coatings. It promotes

the use of anti-reflective coatings on eyewear through education,

marketing, public relations and advertising.

Anti-Reflection Lens Coating Overview

AR

improves a Patient's appearance by making their lenses appear

to

be virtually invisible by reducing the glare on the surface

of the lenses.

And the Patient's vision is improved due to the transmission

of more light.

The

most obvious and demonstrable advantage in the use of an AR

coating is its visual and cosmetic improvement qualities. AR

coating reduces reflections off the front and back surfaces

of the lens that allow many people to actually see better, especially

at night.

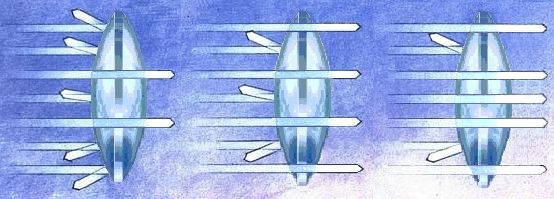

From left to right are lenses

without coating, single coated, and multicoated.

From the first to the third image the light transmission improved

from 96% to 99.5%.

Anti-reflective coatings have been popular for many years in

Europe and Asia because of the visual and cosmetic improvements

to the wearer. It is estimated that only about 12-15% of optical

prescriptions in the United States are coated with AR, compared

with 65% in Europe and 95% in Japan. Part of the reason for

the relatively low acceptance in the United States is the popularity

of plastic lenses; it is more difficult to reduce reflections

on plastic lenses than it is on glass. While anti-reflective

coatings have obtained a reputation as being difficult to clean

and easy to scratch, recent improvements in coating and lens

technology have begun to overcome these earlier objections resulting

in a more viable product.

It was in 1892 when the principle of “thin film coating”

was first discovered. Dennis Taylor, an English scientist, found

that an older lens that had been oxidized would transmit more

light than a newer lens. The cause of this phenomena was tarnish

which had, with time, accumulated on the lens through oxidation.

Taylor accidentally discovered that the tarnish caused improved

light transmittance through the lens. By 1904, Taylor patented

a method for artificially aging lenses by using a method of

chemical treatment.

Forty-three years later modern AR coatings were developed in

Germany, but were held by the government for military reasons

until 1939. The first introduction for ophthalmic purposes didn’t

come until 1957 for the glass market and 1974 for plastic ophthalmic

lenses. This early introduction was in Europe only.

An AR coating is a very thin film. Because it is less than one

wave length of light in thickness it is measured in angstroms,

which is one-tenth of a billionth of a meter. A simple analogy

may work better in understanding a “thin film” coating.

Imagine a plaster wall 150 feet thick with a covering of wallpaper.

That proportion of wallpaper would equal the thin film of AR

coating on the front of a lens 2 mm thick.

Examples of the latest in thin film AR Coating

At left a single coated lens using

thin film in the 1950's - 1970's.

At right a more recent lens. Green-purple reflections means

all lenses are multicoated.

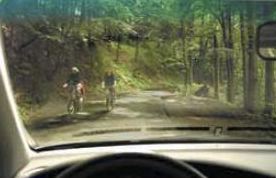

AR coated lenses can also significantly improve night driving

vision. The contrast of bright lights from oncoming cars against

the blackness of night increases the incidence of noticeable

reflections for the wearer which can effect visual acuity.

One of the most frequent complaints

of eyeglass wearers is the

"halo" or "starburst" effect from lights

at night. AR significantly reduces

these effects, producing a remarkable improvement in night vision.

This is especially true while

driving at night. Reduced glare from surrounding

lights as well as oncoming headlights enables you to drive more

safely at night.

Anti-reflective coatings are part of a larger family of “thin

film” coatings which can be deposited on a lens or other

transparent media by a process of vacuum deposition. You would

not want to buy a multiple lens system, like those found in

microscopes, telescopes, binoculars or cameras, without an excellent

anti-reflective coating applied. Each lens in the instrument

would reduce the light transmitted to the eye in succession.

Thus, the object being viewed would appear more dimly lit or

less bright than it would with AR coating. Multiple lens systems

with AR coatings have been used for years by manufacturers of

quality cameras. Without a good AR coating, “ghost”

images caused by internal reflections, can appear and ruin your

photographs.

General

uses of AR Coated Lenses

Ophthalmic

Optics

Ophthalmic

Optics

Laser Mirrors

Laser Mirrors

Microscopes

Microscopes

Binoculars

Binoculars

Aircraft

Instruments

Aircraft

Instruments

Precision

Optics

Precision

Optics

Cameras

Cameras

Ophthalmic

Optics

Ophthalmic

Optics

Although

the reflections most obvious to the observer are seen from the

front surface of the lens, half of the reflections seen by the

observer standing in front of the person wearing the glasses

are, in fact, caused by the rear surface of the lens. Bright

objects to the rear of the wearer will also cause a reflection

from the front and rear surface of the lens to the wearer’s

eye.

One of the most common reflections is that of the wearer’s

own eye. These reflections are generated from both the front

and rear surface of the lens and will include the wearer’s

eyelashes and facial skin in the immediate area of the lens.

These so-called “ghost” images are reflected toward

the optical center of a minus lens. Reflections will not exceed

more than 8% of the total light or 4% per surface as a general

rule, but represent a significant number of distractions to

which a wearer will be subjected. These reflections, plus the

reduced light transmitted to the eye, can impact the vision

of the wearer.

Only 92% of light entering an uncoated CR-39 lens is transmitted

through the lens; with a multi-layer coating that number increases

to nearly 99.5%. Both sides of a lens should be coated to maximize

efficiency. A multi-layered anti-reflection coating for the

lenses will improve the aesthetics of a high refractive index

material (1.6 or greater) more than CR 39 because high refractive

index materials naturally reflect more light. A material with

a refractive index of 1.6 transmits only about 87% of incident

light with 13% lost to reflections. An anti-reflection coating

will increase the percentage of transmitted light from 87% to

99%. AR coating is also especially effective with aspheric lenses

since the flatter back surfaces tend to create more back side

reflections.

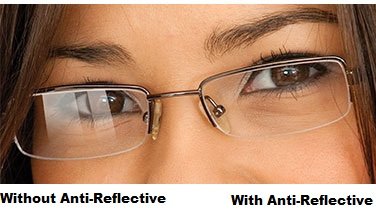

At

left an untreated lens displays glare.

At right an AR coated lens. Light transmission is improved by

4%.

When light enters the lens, a portion of that light is reflected

from the front surface; about 4%. This means that light transmittance

is reduced by 4%. This happens again on the rear surface of

the lens, but for this discussion only the front surface will

be considered.

To better understand how AR coating works, lets review the basics

of wave theory. We’ll start with an analogy. Imagine two

stones thrown into a pond or rain drops hitting a puddle. The

waves emerging from two stones or drops of water eventually

run into each other canceling each other out. This is actually

the theory of “wave interference” at work. There

is positive or “constructive interference” and negative

or “destructive” interference.

Let’s look at constructive interference with this simple

example. One pile of sand added to another equals a pile twice

as high. Add a pile of sand to a hole in the ground of the same

volume and zero is the result. This is a visual example of destructive

interference.

Constructive

Interference

Add two piles of sand together and the result is a pile of sand

twice as high.

Destructive Interference

Add a pile of sand to a hole in the ground of the same volume

and the result is zero.

Anti-Reflection Coating

Technical Aspects

Returning

to the light wave, the same principle applies. Add the “plus”

waves together and the height of the new wave doubles. That

is constructive interference. But reverse one of the waves or

make a negative image of it, and then add the plus wave and

the minus wave. The result is zero. That is destructive interference.

Now consider the lens and how this application works to help.

Light waves enter an uncoated lens at obtuse angles causing

reflections on both sides of the lenses. After the AR coating

has been applied only direct light is allowed to pass through

the lens. This occurs because the thickness of the coating is

measured precisely in wave length thickness. To be more precise,

it is one quarter of a wavelength. This means that the waves

travels one quarter of its own length from the front surface

of the coating to the front surface of the lens. Then it travels

another quarter of its own length to leave the surface after

being reflected from the front surface of the lens. This is

an important concept if we are to understand how an anti-reflective

coating works. A light wave has now traveled one half of its

own length, thereby reversing itself against the next one and

the one before it. The waves create destructive interference

and cancel each other.

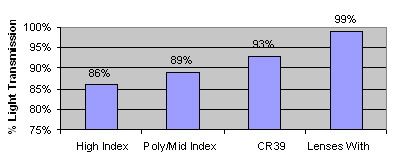

Light

transmission of different lens materials with and without AR

coating

Without

AR Without AR Without

AR AR

Since one coating layer is precisely matched to eliminate one

wavelength, other wavelengths (or colors) are not eliminated

completely. By adding additional layers of coatings to the surface,

additional wavelengths can be eliminated. This becomes a complex

formula best completed by computer. Each manufacturer has a

formula which is proprietary and felt to be their edge in this

competitive market. When measured on a spectrophotometer, each

of these individually formulated coatings appear differently

and become the AR coating “fingerprint” of that

manufacturer.

Every AR coating exhibits some residual color seen in the reflections

of even a multi-layer coating. The color is significantly less

in a multi-layer coating as compared to a bi-layer coating,

however. The variations in color and intensity sometimes helps

to identify the manufacturer of the coated product.

If a five layer coating is better than a two layer coating,

does that mean that a 20 layer coating would be better still?

AR coating efficiently is not directly improved by the number

of layers, so much as by what each layer contributes to the

reduction in reflection. Once again, the formulation of types

and thickness of each material to be used in the five layer

matrix becomes the priority in this very highly technical area

of optics.

In fact, it is only due to refinements in both coating equipment

and computers used to run them that these multi-layer coatings

can be enjoyed by the Patients. The actual process of AR coating

has evolved significantly over the last 50 years and is truly

a state-of-the-art “high tech” process which utilizes

a vacuum deposition technology. Modern AR coating equipment

has been known to cost between $500,000.00 and $1,000,000.00.

Keeping

lenses free of smudges and spots is a daily nuisance.

The process includes a hydrophobic/oleophobic layer applied

to the exterior of both sides of the lenses, which creates a

protective shield that repels water, dirt, dust and even oils.

This super smooth surface helps to keep lenses cleaner.

The photos above are of a

drop of water on top of of two lenses,

one with AR and the other uncoated. Notice how the droplet on

the left actually"beads up" or repels the water as

the surface

tension is removed by the AR coating, while the uncoated

lens on the right actual pulls the water toward the surface

of the lens. The same is true for dust dirt and even oil. Also

notice how the surface of the uncoated lens is much

more visible that that of the uncoated lens.

To begin the coating process, lenses must be carefully inspected

for scratches or surfacing imperfections. Lenses are thoroughly

cleaned to ensure good adhesion of the coating to the surface

of the lens. Sophisticated ultrasonic cleaning processes are

used by most coating companies, which utilize many cleaning

and rinse cycles.

Once thoroughly cleaned, the lens is inspected once again to

make sure that it has been properly cleaned (if a wax has been

applied to hide lens imperfections this cleaning will remove

the wax, highlight the scratches and make them more visible

after coating). Rejected lenses will be returned to the lab

to be remade.

The lens is placed in a degassing oven to assure that all moisture

has been removed. This is an important step to make the coating

process faster and efficient.

A typical vacuum coating machine has a rotating lens rack at

the top of the unit. A monitoring device measures coating thickness.

The machine actually measures the change in the frequency of

an oscillating quartz crystal. The frequency of the crystal

changes as the coating builds on its surface. Optical monitors

can also be used in some cases. As the coating builds with the

oscillating quartz crystal, the mechanical energy is changed

to electrical energy and is fed into a computer for precise

layer thickness. The composition and formulation of the materials

evaporated onto the lens are proprietary. An electron beam gun

evaporates the material to be used in the coating application.

Vaporized molecules travel through the chamber to adhere to

the lens surface. In a multiple layer coating system the computer

controls the time and sequence of the deposition of coatings

per side during operation.

A microscopic view of a typical AR coated surface shows very

porous and bumpy areas in which oils and debris can accumulate

on the last hard AR layer. Lenses seem dirty, oily and smudgy

as a result of this porosity. A significant enhancement to the

AR coating process is the application of an additional layer

to fill in this porous material to provide a smooth, slick surface.

This aids in abrasion resistance and makes the lenses easier

to clean than any uncoated lenses. After the hydrophobic coating

application the lenses are annealed for a tight chemical bond.

As many of you know, AR coating with a hydrophobic coat make

the lenses much easier to care for and as with AR coating–the

hydrophobic coating will continue to be improved.

Preparing

lenses for AR Coating

Preparing

lenses for AR Coating

Inspection

and Cleaning

Before being sent to the coating lab, the lenses must be thoroughly

cleaned and inspected in your office. A slight blemish or scratch

which may go unnoticed on an uncoated lens becomes much more

visible once the lens is coated. It’s best to inspect

the lenses under a bright light, such as a halogen lamp, to

get an idea what the lenses will look like after coating.

The lenses are inspected again by the lab, then thoroughly cleaned

with alcohol to remove any markings or dried edger material.

In the coating lab, the lenses are subjected to a series of

ultrasonic baths which make them “raw” so they can

accept a base to which the AR coating can adhere. The lenses

are then baked in an oven to remove any excess moisture, since

excessive moisture can cause adhesion problems. Finally, the

lenses are placed in a vacuum chamber for the coating process

where a layer of binding material, either chromium or silicon

monoxide, is applied to the lens surface.

Know your lenses. Virtually any lens can be AR coated, including

laminates and photochromics. However, AR coating does affect

the changeability of photochromics slightly. Lenses should always

be coated in pairs to avoid slight variations in residual color.

It’s best to provide the coating lab with ample information

about the lenses including, lens material, manufacturer, color,

and any in-office treatments you’ve applied including

UV dye.

Tips

for Cutting and Edging

lenses that are to be AR Coated

Organize

edging jobs so that all like materials are cut at the same time,

i.e., don’t cut CR39 after a glass job.

Organize

edging jobs so that all like materials are cut at the same time,

i.e., don’t cut CR39 after a glass job.

Avoid cutting

plastic lenses on a glass edger.

Avoid cutting

plastic lenses on a glass edger.

Wash you

system down with water spray to remove any lens material remaining

on the machine.

Wash you

system down with water spray to remove any lens material remaining

on the machine.

Use separate

coolant buckets for glass and plastic jobs.

Use separate

coolant buckets for glass and plastic jobs.

Be certain

chuck pressure is correct when lenses are edged.

Be certain

chuck pressure is correct when lenses are edged.

Change chuck

pads when changing material.

Change chuck

pads when changing material.

Use surface-saver

tape when edging, edge-polishing or grooving then remove the

tape immediately after processing.

Use surface-saver

tape when edging, edge-polishing or grooving then remove the

tape immediately after processing.

Be sure lenses

are free from any kind of edger slurry and that they are free

from layout marks before shipping to the coating lab.

Be sure lenses

are free from any kind of edger slurry and that they are free

from layout marks before shipping to the coating lab.

AR Coated Lenses

Cosmetic Considerations

Edge Polishing

Edge Polishing

Edge polishing should be done before the lenses are coated.

Although the lens edges are not coated, any reflections that

come through the edges are usually minuscule. While edge polishes

and AR coating can work well together, both a polished edge

and a frosted sample should be demonstrated to the Patient.

Tinting

Tinting

If the lenses are going to be tinted, this must be done before

being sent to the AR lab. Cosmetic tints reduce light transmission

slightly, counteracting the purpose of AR. Coating the lenses

makes them virtually invisible, tints make them visible again.

Also, the color may not exactly match the sample since AR coating

has its own residual color. For best results tint the lenses

about 15% darker, then bleach out the excess color until it

is about 5% to 10% darker than the end result you want. This

will remove any surface dye and stabilize the color. UV treated

lenses can also be AR coated. The back surface of sun lenses

are often tinted to minimize reflections from light coming from

the side or back of the wearer.

Selecting

an AR Coating laboratory

Lenses can be sent directly to a coating lab or they can be

sent to the surfacing lab who may act as a middleman. The performance

of the lab can be as important as the performance of the coating

since customer service is critical to your success. Any questions

you might have regarding AR coating should be answered quickly

and politely. The cost of having lenses coated will vary according

to the type of lenses being used, whether one side or both is

being coated, and the amount of work the lab does for you.

Most AR coaters provide same day turn-around within their labs,

which means three business days when transportation time is

factored in. The coating lab should be able to provide support

in an effort to educate Patients about the benefits of AR coating,

and the Dispenser with marketing support such as point of purchase

materials, and with the technical aspects of dispensing AR.

Presenting

AR Coating

The Refractionist can play an important role in presenting AR

coating. The discussion of AR should begin in the exam room

and be seen as an opportunity to educate Patients on the benefits

of AR. Lifestyle information can be gathered verbally, or when

the Patient completes a questionnaire. Either method can be

used as a lead-in to presenting information about AR coating,

or any other premium lens product such as high index materials

or aspheric's. AR coating could be written on the Rx, and it

should be worn by the office staff.

After the exam, the Patient should be introduced to the Dispenser

and the Refractionist may explain any lens options that were

discussed with the Patient. If the Patient has selected high

index lenses AR coating is especially important since high index

materials reflect more light than conventional lenses. Many

Practitioners coat the back surface of sunglass lenses to minimize

reflections when the sun is located to the side or behind the

Patient’s head. AR coated photochromics can improve light

transmission at night while reducing back surface reflections.

Benefits

To Be Emphasized

Benefits

To Be Emphasized

Visual Clarity

- AR allows 8% more light to enter the eye. That is, 8% less

light is reflected away from the eye on the front surface of

the lens so more light is made available for vision. The result

is clearer, sharper vision and reduced eyestrain, which benefits

everyone.

Visual Clarity

- AR allows 8% more light to enter the eye. That is, 8% less

light is reflected away from the eye on the front surface of

the lens so more light is made available for vision. The result

is clearer, sharper vision and reduced eyestrain, which benefits

everyone.

Occupational

- Fluorescent lighting, computers, cash registers, etc., all

cause an increase of reflections in the workplace. This increase

in reflections causes eyestrain, headaches, fatigue and a decrease

in work productivity.

Occupational

- Fluorescent lighting, computers, cash registers, etc., all

cause an increase of reflections in the workplace. This increase

in reflections causes eyestrain, headaches, fatigue and a decrease

in work productivity.

Night driving

- External reflections are a major problem when it comes to

driving safely at night. The reflections from oncoming headlights,

streetlamps, and the road can cause distractions and discomfort

to the driver. Internal reflections can cause ghost images and

result in a decrease in reaction time.

Night driving

- External reflections are a major problem when it comes to

driving safely at night. The reflections from oncoming headlights,

streetlamps, and the road can cause distractions and discomfort

to the driver. Internal reflections can cause ghost images and

result in a decrease in reaction time.

Sunwear -

Backside AR can eliminate a couple of problems related to sunwear.

First is the annoying image of the eye that is reflected in

the center of the lens and can be very distracting. The second

is the glare hazard that is caused by the mirror effect of a

dark lens. With sun lenses, light from behind the wearer can

be reflected directly into the eye from the back of the lens

surface causing discomfort. Note: AR coatings are no applied

to the front surface of a polarized lens because it affects

the polarization process and can reduce the darkness of the

polarized lens by as much as 8%.

Sunwear -

Backside AR can eliminate a couple of problems related to sunwear.

First is the annoying image of the eye that is reflected in

the center of the lens and can be very distracting. The second

is the glare hazard that is caused by the mirror effect of a

dark lens. With sun lenses, light from behind the wearer can

be reflected directly into the eye from the back of the lens

surface causing discomfort. Note: AR coatings are no applied

to the front surface of a polarized lens because it affects

the polarization process and can reduce the darkness of the

polarized lens by as much as 8%.

Cosmetic

- Shakespeare once said, “The eyes are the window to the

soul.” If reflections are inhibiting eye contact and eye

visibility, much can be lost. AR coating enhances not only the

appearance of the Patient but can increase the effectiveness

of communication by enabling better eye contact.

Cosmetic

- Shakespeare once said, “The eyes are the window to the

soul.” If reflections are inhibiting eye contact and eye

visibility, much can be lost. AR coating enhances not only the

appearance of the Patient but can increase the effectiveness

of communication by enabling better eye contact.

Demonstration kits can be used when presenting AR coating to

the Patient. The cosmetic benefits of AR can be easily demonstrated

by placing two plano lenses in an attractive frame, one AR coated

and the other not. The Dispenser should place the frame on the

Patient and point out the cosmetic appeal of the coated lens.

An especially effective method of demonstrating improved contrast

enhancement of AR coated lenses is to hold a partially coated

lens over printed material. The coated portion of the lens will

produce a sharper crisper image.

When pricing AR coating, many Practitioners “bundle”

the cost of AR into the lens price and consider it an integral

part of the lens choice.

Provide excellent customer service with personalized attention

and concern for ascertaining the needs of your Patient, then

using your professional expertise to help them fill those needs.

Finally, its important to educate Patients on the proper care

and maintenance of their AR coated lenses. Some suggestions

for a Patient Handout on the care and maintenance of AR coated

lenses follows.

Frequently

asked questions about AR Coating

Should

AR coating be applied to Transitions lenses?

Yes. The

AR coating creates an oxygen barrier and prolongs the life of

the lens. Normally, without AR coatings the photochromics could

break down as much as 22-23% after two years. With AR coating,

the maximum break down is 16%. There is no loss in speed of

activation and there is minimal-insignificant speed of fade

with an AR coating.

Yes. The

AR coating creates an oxygen barrier and prolongs the life of

the lens. Normally, without AR coatings the photochromics could

break down as much as 22-23% after two years. With AR coating,

the maximum break down is 16%. There is no loss in speed of

activation and there is minimal-insignificant speed of fade

with an AR coating.

Do AR coatings have any UV protection?

No. AR coatings

do not contain any UV protection.

No. AR coatings

do not contain any UV protection.

Can lenses be tinted after they have been AR coated?

No. Tinting

needs to be done before the lenses are AR coated.

No. Tinting

needs to be done before the lenses are AR coated.

Patient

handouts are recommended for

Care and Cleaning of AR Coated Lenses

AR coatings, as they are called, virtually eliminate the reflections,

such as the images of your own eyes and eyelashes, from the

back sides of lenses. AR coatings also let more light reach

your eyes through the front side of the lenses, increasing contrast

and clarity. This means that you actually see better - particularly

in such low-light situations as night driving.

AR coating will also significantly reduce light reflections

from the front of lenses, making them seem almost invisible.

People will focus on your eyes, not on your eyeglasses, and

when appearing in photographs or on video, your eyes will be

much more visible.

Clean your new lenses carefully.

Just as your fine jewelry or delicate camera lenses must be

cared for properly, AR coated lenses also need a little TLC

so that they can continue to perform well.

AR

Cleaning Tips

AR

Cleaning Tips

Rinse the

lenses under the tap with lukewarm water.

Rinse the

lenses under the tap with lukewarm water.

Place a drop

of a mild hand soap or dishwashing liquid on each lens. (Dawn

and Joy are ideal. Don’t use soap that contains hand cream

- this will smear the lenses.)

Place a drop

of a mild hand soap or dishwashing liquid on each lens. (Dawn

and Joy are ideal. Don’t use soap that contains hand cream

- this will smear the lenses.)

With your

fingers, rub the soap on both sides of each lens for about 5

seconds per lens, then rinse under the tap.

With your

fingers, rub the soap on both sides of each lens for about 5

seconds per lens, then rinse under the tap.

Use a clean,

lint-free cotton towel or a special microfiber cloth available

from your optical dispensary to gently wipe each lens dry. Wash

your microfiber cloths once a week, without a fabric softener

to avoid an accumulation of body oils.

Use a clean,

lint-free cotton towel or a special microfiber cloth available

from your optical dispensary to gently wipe each lens dry. Wash

your microfiber cloths once a week, without a fabric softener

to avoid an accumulation of body oils.

Do not “polish”

your lenses - just remove the water. Avoid using most tissues

or paper towels. Paper products are made from wood and many

contain small particles that can scratch your lenses. Use care

in using any cloths also, because the weave may be rough enough

to scratch the lenses.

Do not “polish”

your lenses - just remove the water. Avoid using most tissues

or paper towels. Paper products are made from wood and many

contain small particles that can scratch your lenses. Use care

in using any cloths also, because the weave may be rough enough

to scratch the lenses.

Clean your

lenses at least once daily.

Clean your

lenses at least once daily.

Any

attempt to clean coated lenses without first removing any tiny,

abrasive material by rinsing or at least blowing off any surface

particles may result in unwanted scratches. Remember, today's

surface coatings are extra thin, therefore they require extra

care.

When

there’s no water

If you need to clean your AR lenses when you do not have access

to running water, you will need to take certain precautions

to ensure that you do not scratch the lenses:

Use a spray

cleaner that is specially formulated for AR lenses, thoroughly

wetting each side of the lens and wiping them dry with a microfiber

cloth.

Use a spray

cleaner that is specially formulated for AR lenses, thoroughly

wetting each side of the lens and wiping them dry with a microfiber

cloth.

Never attempt

to clean your AR lenses dry if there is visible dirt on them.

Rubbing the lenses when they are dirty may scratch them.

Never attempt

to clean your AR lenses dry if there is visible dirt on them.

Rubbing the lenses when they are dirty may scratch them.

If the lenses

are not dirty, only smudged, as with a fingerprint for example,

use the special AR microfiber cleaning cloth to gently remove

the oils.

If the lenses

are not dirty, only smudged, as with a fingerprint for example,

use the special AR microfiber cleaning cloth to gently remove

the oils.

Common

Sense

Use common sense to care for your glasses when you’re

not wearing them to protect your lenses:

Keep your

glasses in their case when they’re not on your face.

Keep your

glasses in their case when they’re not on your face.

If you remove

your glasses from time to time during the day, place them in

their case. If you can’t keep your case handy, be sure

that you do not rest the glasses face-down on the lenses. Also,

keep the temples unfolded (just as they are when you remove

them from your face) so that the temples do not meet the lenses

and scratch them at the contact points.

If you remove

your glasses from time to time during the day, place them in

their case. If you can’t keep your case handy, be sure

that you do not rest the glasses face-down on the lenses. Also,

keep the temples unfolded (just as they are when you remove

them from your face) so that the temples do not meet the lenses

and scratch them at the contact points.

Rest the

glasses upside down on a flat surface. This will reduce their

chances of tipping over onto the lenses and scratching. --

Rest the

glasses upside down on a flat surface. This will reduce their

chances of tipping over onto the lenses and scratching. --